UCT understands customers often need more than just a coating supplier. We offer both coating products and surface engineering service. Successful integration of coatings with components requires integration of mechanical, materials science, and industrial engineering. UCT engineers work with our customers’ engineers to match customer specified performance requirements with the correct coating and coating processes.

Our customers typically have a strong understanding of the mechanical engineering driving their applications and usually have some understanding of material selection, but may not have much knowledge of coatings or coating processes. UCT is fully staffed with surface engineering professionals and all of the analytical equipment required to participate in the selection of the right solution, to generate supporting technical results, and to mature an application from first-contact to volume production.

There are times when solutions require more than our standard application development effort. UCT has the R&D staff and high tech relationships to deliver custom solutions per customer requirements. We can partner with our customers to develop such solutions, taking advantage of the strengths each brings to the effort.

We have compressed the time to adoption by having separate R&D, application development, and production capabilities that have steep on-ramps between each.

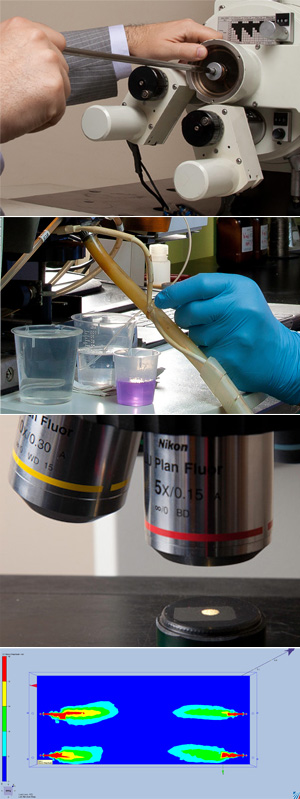

Internal Analytical Capabilities

- Microscopes – materials science, failure analysis

- Optical microscopy

- Scanning electron microscopy, Energy Dispersive Spectroscopy

- Hardness – hardness of materials

- Knoop microhardness

- Vickers microhardness

- Metallurgical sample preparation

- Topogrpahical analysis

- Cross-sectional analysis

- Chemical titration – chemical analysis

- Atomic absorption – ppm metals analysis in chemistry

- Inductive coupled plasma – ppm / ppb metals and non-metals analysis in chemistry

- Xray fluorescence – coating thickness

- Block & Ring – mechanical wear, coefficient of friction

- Profilometer – surface roughness

- Coordinate measurement machine – dimensional assessment on complicated geometry

- Standard gages – specific dimensional analysis

- Adhesion – impact, bend

- Corrosion – salt fog, various acid corrosion tests

- Custom testing as required

External Testing Facilities

We have strong university and National Lab relationships, which give us access to most advanced analytical equipment available.

Government Application Development

- ITAR registered

- FFL licensed

- Recipient of Government supported development and commercialization projects since 2003.

- SBIR qualified (<500 employees)