Quality Management System

UCT Coatings’ Quality Management System has been certified as being in conformity with AS-9100. UCT has been audited and registered by Intertek as meeting the requirements for AS9100:D and ISO 9001:2015 standards.

The standard is recognized worldwide, and the aerospace industry has moved toward requiring their subcontractors and suppliers to be AS9100 certified. By becoming registered to AS9100 UCT will gain a competitive advantage and benefit from the improved processes and continuous improvement that is the foundation of ISO 9001 certified Quality Management Systems.

• Our Certificate Number is 98604-00 and the Certificate Expiry Date: February 4, 2026.

• Click Here to view the Certificate of Registration.

NADCAP Certification

UCT Coatings, Inc. has received its accreditation with NADCAP for Chemical Processing. This accomplishment indicates an extensive review, documentation and audit by NADCAP and certifies that we have met or exceeded industry standards set forth by key stakeholders in the aerospace and defense industry.

A NADCAP certification, among other things, ensures the following:

• Improved product quality and consistency

• Maintaining a high level of customer satisfaction

• Implementation of best industry practices

• Fewer audits for end-users and organizations along the supply chain

• Our Certificate Number is 18808208623 and the Certificate Expiry Date is August 31, 2023

• Click Here to view the Certificate of Registration

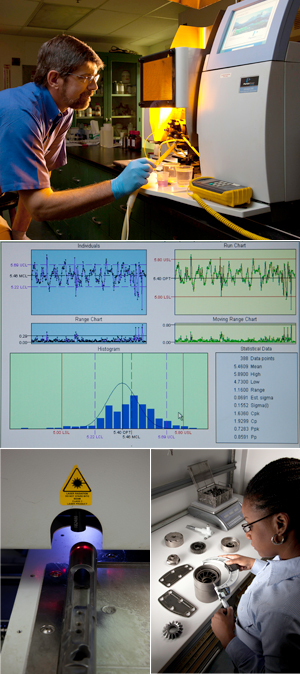

Statistical Process Controls (SPC)

We believe controlling process inputs yields controlled coating outputs. We have developed and use the most advanced process controls in metal finishing. There are approximately (90) parameters that are measured, controlled, and documented throughout our processes including; chemical mixing, chemical processing, coating qualities, and heat treatment. The frequency of measurement for each parameter is sufficient to guarantee adequate control.

Where possible, we use automated processes. Control of the chemistry from which coatings are deposited is the most critical. Measurements are made frequently and chemistry replenishment is made continuously through automated equipment.

- We work to customer specifications, based on engineering drawings. We determine optimal coating type, thickness, surface finish, hardness, and other parameters, in addition to the preferred inspection method.

- A complete written material specification for our proprietary coatings exists and can be used to specify our coatings.

- We are able to provide Certification of Conformance documentation as required by our customers.